GEOVIA Minex™ provides the best geology and mine planning tools for coal and other stratified deposits, ensuring resources are evaluated accurately and mined efficiently.

The recognized world leader of integrated geology and mine planning solutions for coal and other stratified deposits, GEOVIA Minex™ ensures resources are evaluated accurately and mined efficiently from exploration to rehabilitation. As a complete solution, data and skills can be readily moved between teams, delivering significant time and cost savings.

Across the world, mining companies turn to Minex to more accurately design, plan and implement mining strategies which drive additional efficiencies, increase productivity, control costs and increase profitability.

GEOVIA Minex Overview

GEOVIA Minex Customer Case Study

MINEX PROVIDES SOLUTIONS TO KEY INDUSTRY CHALLENGES INCLUDING:

- Quickly and efficiently modeling large, deep and data-intense coal projects.

- Accurately measuring coal quality and washability Reducing costs control related to waste removal and haulage.

- Reducing data duplication.

- Improving workplace efficiency and reduce training and errors.

- Using multiple software packages.

- Communicating model plans to stakeholders.

The recognized world leader of integrated geology and mine planning solutions for coal and other stratified deposits, GEOVIA Minex ensures resources are evaluated accurately and mined efficiently from exploration to rehabilitation. As a complete solution, data and skills can be readily moved between teams, delivering significant time and cost savings. Across the world, mining companies turn to Mines to more accurately design, plan and implement mining strategies which drive additional efficiencies, increase productivity, control costs and increase profitability.

GEOLOGICAL MODELING AND RESOURCE EVALUATION

Minex’s reliable geological modeling tools help geologists manage borehole data, and model and quantify stratified deposits, with support for even the most complex faults, environmental constraints and challenging economic conditions.

OUR SOLUTIONS

Integrated Data Management

- Connects seamlessly to corporate borehole data storage systems including Microsoft Access and SQL Server, Oracle”, and acquire.

- Provides comprehensive tools to facilitate data validation, auditing and resource reporting to meet reporting requirements.

- Supports import and export of Vulcan and Carlson grid files and seam models as well as string data to Auto CAD.

- Project input and output files are managed in one location using Mines’s file management tools.

Mine’s repeatable, fast and accurate modeling tools build entire in minutes.

Modeling

- Repeatable, fast and accurate modeling tools build entine models, including seam floor, thickness and quality in minutes.

- Specialized tools for deposits with faults allow accurate modeling of inclined or curved faults, in normal or reverse fault environments.

- Model the complete coal wash curve so that yield, ash and other analyzes can be estimated across the entire deposit, and used in resource and reserves reports to simulate plant processes by area or schedule time.

- Provides multiple industry-standard estimation tools, including an interface to GSLIB for Kriging and conditional simulation.

- Variogram modeling included in dynamic lag adjustment helps identify the best variograms for the data.

- Validation tools including jack knifing to ensure confidence in the accuracy of geological models.

- Contouring, sectioning, 30 borehole, statistics and histogram displays maximize resource presentations to stakeholders.

MINE PLANNING AND SCHEDULING

Minex’s mine planning functions are integrally linked to the geological model. Planning starts by defining the economic mining areas, so these areas can be targeted during the subsequent pit design phase. Once the pit is designed, the reserves and quality data are stored in a database to provide fast access for viewing, editing and manipulation.

OUR SOLUTION

Open Pit Optimization

- The Minex His Optimizer considers prate and cost to locate and generate a final pit that is break even or optimal at its limits. using the well-known Lerchs Grossman (LQ) algorithm.

- Pit optimization is ideal where pits are deep and the material in the sloping final highwall makes a vertical analysis difficult. For simpler flat lying deposits, Mines provides both vertical and inclined strip ratio calculations.

Open Pit Mine Design

- Powerful and easy-to-use, pit and ramp design tools allow manual or automatic generation of pits or dumps. Ramps are generated as the pit or dump is created, providing instant visualisation of the design.

- Create a road or spoil pile on ang existing mine topography and easily patch this into existing surfaces.

- Mine designs are integrated with the geologic model and optimization output, enabling fast, accurate and timely designs. Minex subdivides the deposit into a set of mining volumes or reserves using the intersection of benches, strips and blocks with the geologic model.

Open Pit Mine Scheduling

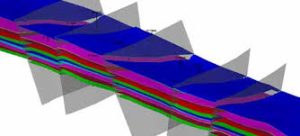

- Detailed Interactive Scheduling Creates schedule by interacting with rich 3D graphic displays generated directly from Minex seam models, pit designs and reserves.

- Target Scheduling Seek a volume or tonnage in a given scheduling period.

- Excellent flexibility in the monitoring of schedules using “live” current period and historical charts and tables.

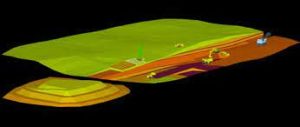

- Visually monitor waste and ore extraction information as a schedule progresses to imperative decision making and to save time by finding and resolving potential problems early in the scheduling process.

- “Play” ang saved schedule to visualize it graphically. This effectively communicates plans to management and operators and visually validates the plan’s practicality.

- Easily perform multiple “what-ifs” by choosing a point in an existing schedule to create a branch to test an alternate scenario. Schedule reporting includes flexible and detailed reports that can be exported directly into Microsoft Excel”.

- 30 interactive scheduling produces quick schedules for decision making

Open Pit Dump Scheduling and Haulage Planning

- Dump Scheduling and Haulage Planning Quick and more accurate decision making related to waste removal and haulage.

- Scenario Manager Organize all tasks related to waste management and haulage in a single interface. Easily create various dump scenarios and take control over the priority, sequence and direction in which dumps are filled.

- Advanced Haulage Planning Effectively analyze truck cycle times and utilization leading to optimized truck fleet and haul road selection, and improved cost control.

- An equipment database enables users to add detailed equipment properties and performance characteristics and accurately estimate haul cycle times from waste blocks in each pit to defined pit exit points.

- Enhanced reporting provides mine planners with the flexibility to summarize the movement of waste and effectively communicate results to key stakeholders.

- Advanced reporting tools allow for quick comparisons between haulage options, leading to the identification and selection of the lowest cost and best alternatives.

- Critical decisions across the business are communicated easily with a visual 3D playback animation function.

The Dump Scheduling and Haulage Planning module delivers a realistic simulation of the short-term mining plan

Open Pit Short-Term Production

- Interface with a variety of modern Survey GPS instruments to downloed from the field or upload for peg out.

- Quickly and easily design blasts in 3D and upload to equipment for GPS drilling control.

- Build maximum dumps to an elevation, a design surface (such as a permitted limit), or until a desired volume is achieved.

- Design dragline dumps.

Underground Mine Design

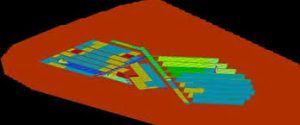

- Create detail underground mine designs using set of rich and interactive tours that provide instant design visualization as it unfolds.

- Quick Layout Tool-Create panels for either longwall or bord and piller layouts based on panel configurations and working types with just a few keystrokes.

- 3D Reserves Display-Display the mine design and colour each block based on a single color, working type or a quality variable.

- Automate the complex process of calculating underground reserves values.

Underground Mine Scheduling

- The Mines environment enables interactive scheduling with point and click simplicity and the ability to see bottlenecks, downtime, resource allocation and workflow feasibility.

- Multiple scheduling scenarios can be quickly developed using a set of interactive tools which provide the means to decide on the most effective alternative, optimizing equipment within selected mining precedence constraints.

- Optimize equipment within selected mining locations and constraints.

Visualize your underground mine design and scheduling.

Mine Rehabilitation

Minex’s mine rehabilitation functions are integrally linked to other planning processes, allowing successful planning of the construction and rehabilitation of final landforms.

OUR SOLUTIONS

- Staged dumps can be quickly designed from the excavation surface to an elevation or landform design. Dump volumes can be progressively matched to the schedule period volumes ensuring the dumps are practical.

- Cross Section Rehabilitation-Simplifies the complex task of dozing down a truck shovel dump to form a final rehabilitation surface.

- Spoil Reshaping-Smoothest mine dumps into a final landform that meets environmental limits while minimizing reshaping costs.

- Minimize dozing while meeting elevation and slope restraints.

GEOVIA Surpac Mine Planning FAQ

Which mining software is used for mine planning?

GEOVIA Surpac is a widely used software in the field of mine planning. It offers a range of tools and functionalities essential for effective mine design and geological interpretation. Some of its key features include:

- Geological Modeling: Allows for detailed 3D modeling of geological data, aiding in the accurate estimation of mineral resources.

- Mine Design: Provides tools for both surface and underground mine design, enabling planners to create efficient and practical mining layouts.

- Mine Planning and Scheduling: Facilitates the creation of comprehensive plans and schedules, optimizing the sequence of mining operations to maximize resource extraction.

- Data Integration: Capable of integrating various types of data, including geological, environmental, and operational, to provide a comprehensive view of the mining project.

By using GEOVIA Surpac, mining engineers and planners can make more informed decisions, leading to improved efficiency, safety, and profitability of mining operations.

What is mine planning?

Mine planning is a critical process in mining operations, encompassing:

- Resource Assessment and Feasibility Studies: This involves geological exploration to estimate the size and quality of mineral deposits and conducting studies to evaluate the economic, technical, and environmental viability of mining these resources.

- Design and Engineering: Involves creating detailed designs of the mine layout, including the mining method, access routes, and processing facilities, while considering geological and environmental factors.

- Scheduling, Budgeting, and Regulatory Compliance: Focuses on planning the sequence of extraction, allocating resources, budget management, and ensuring compliance with all relevant safety and environmental regulations.

- Environmental Management and Safety Planning: Includes strategies to minimize environmental impacts and ensuring the safety of operations through measures like waste management, reclamation, and emergency response planning.